eLearning (also called online learning or virtual training) has been a viable alternative to classroom learning for over 20 years. But cost-effectiveness and familiarity mean it’s now becoming the go-to option for employee training in food manufacturing.

A big reason for this is Covid-19. When the pandemic hit, it changed the training landscape.

Food manufacturers had to deal with all kinds of challenges: furloughed personnel, employers off sick, social distancing at work, and running a business with many staff working from home.

Common activities like in-person meetings and training weren’t possible.

So, alternative ways of working become relied-upon ways of working. Online meeting apps like Zoom and Microsoft Teams replaced the boardroom table and eLearning replaced the classroom.

Fast-forward to now. Most of us are happy and confident using online platforms. And companies can reap the rewards.

Why?

Because eLearning and virtual training are much more cost-efficient than traditional training.

As noted by the Chartered Institute of Managers’ Post-COVID-19 Economy Literature Review:

“Digital learning has been shown to require less time for learning, with a study by the Brandon Hall Group revealing that digital learning required 40-60% less time to learn than traditional classroom learning, reducing one of the significant costs of training as learners can study at their own pace.”

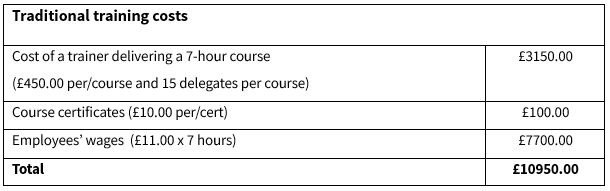

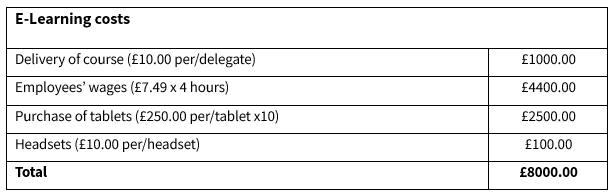

So, how does this translate to the real world? Let’s compare the direct costs of a company training 100 employees in basic food safety.

Note: Course certificates are included in the cost of the course with tolearn eLearning courses.

It’s 30% more expensive for a company to use traditional training methods. And that’s without the cost of travel, venue hire, food, and accommodation if training is delivered off-site. All of which can add thousands of pounds to a budget sheet.

Of course, cost isn’t everything. First and foremost, training has to benefit the employee. They have to be able to understand and remember what they learn to put it into practice.

eLearning is shown to outperform traditional training in this area too. As noted in the Chartered Institute of Managers’ study:

“Retention rates from digital learning were between 25% and 60% compared with only 8-10% in a traditional classroom setting. This is attributed to learners having more control over the learning process, allowing them to focus on the most relevant material. “

By reducing training time, eLearning also cuts down on the time a learner spends away from their job. The flexibility of learning at their own pace, from any location means training can be done outside of important work duties. So processes aren’t affected and productivity doesn’t dip.

In the last decade, eLearning has evolved into an efficient and interactive form of training to rival classroom training. And one that makes sense to any food manufacturing company.

See how eLearning courses can benefit your food company, financially and practically. Use our interactive calendar to book a free demo with a tolearn expert at a date and time that suits you.