Understanding Food Safety: what is meant by

a kill step, six log reduction and full cook

1. Introduction

As part of the BRCGS Food Safety Global Standard requirements for safe food manufacturing, you’ll see three terms mentioned in relation to cooking:

- Kill step

- 6-log reduction

- Full cook

All three used to deliver the same outcome: ensure food is thoroughly cooked to kill harmful bacteria that could cause food poisoning.

But what do they mean?

To understand this, you need to understand what a colony-forming unit is.

Colony forming units are counted in the mathematical function known as logs. 1 log is a range of 0-10 colony-forming units. As logs increase from 1 to 2 and 2 to 3 etc, CFUs grow by a factor of 10.

Here’s a table to show how CFUs massively increase with each log increase:

Log Number of CFUs

1 = 0 – 10

2 = 11 – 100

3 = 1001 – 1000

4 = 1001 – 10,000

5 = 10,001 – 100,000

6 = 100,001 – 1,000,000

How log reduction works

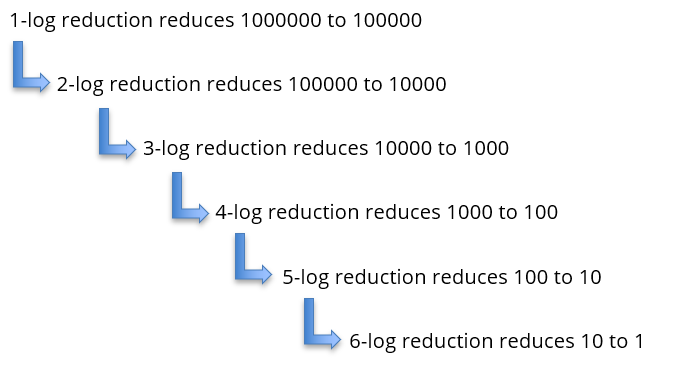

Log reduction refers to killing colony-forming units. So, a 1-log reduction will kill 90% of CFUs, reducing the count by a factor of 10.

If you have 1,000,000 (one million) CFUs and you want to reduce it to 1 CFU (killing 99.9999% of bacteria or fungi), you need a 6-log reduction.

Here’s an example of how a 6-log reduction works:

2. The steps required to create and count Colony Forming Units?

A colony-forming unit (CFU) is a measure of the number of live bacterial or fungal cells in a sample. CFU counts help measure microorganism limits to ensure working areas are safe for production, food is safe for consumption and the environment complies with regulatory standards.

Here’s how to identify and count colony-forming units and starts with taking a sample:

Taking a sample

Personnel taking samples should wear gloves and the gloved hand should thoroughly disinfected with an alcohol wipe. It is good practice to use a sterilized template and where the same template is being used for multiple samples, a fresh alcohol wipe can be used to clean and disinfect the template between samples.

The sample is taken by rubbing the swap on the surface horizontally and verticaly using the template as a guide.

Send the swab to a laboratory as soon as possible after taking it (ideally, within 24 hours). Keep samples chilled and avoid cross-contamination from dirty hands or clothing.

The next part is handled by the laboratory.

Once the laboratory has your swab, a petri dish containing a agar growth medium is prepared. The swab is gently rubbed across the surface of the agar to transfer any bacteria to the petri dish.

The petri dish is then placed into an incubator to set the optimal temperature for the organisms to grow, as well as a suitable time frame for growth. During incubation, the bacteria goes through a process called binary fission. This is when bacteria splits to form two bacteria. Over time, the doubling of bacteria produces a visible colony.

The petri dish is removed from the oven. The colony forming units can then be counted using a microscope. These are reported as a number and a mathamatical function know as a log.

Counting colony forming units

To achieve a 6-log reduction, you have to work out the core temperature of a product and the time required to reduce CFUs to 1. Thankfully, there’s already a set calculation for this: 70°C for 2 minutes or equivalent (hotter temperature requires less time, lower temperature requires more time). Additional guidance is given on temperature and time in the BRCGS Global Standard Food Safety Appendix 3.

In simple terms, if you’re cooking chicken and want it to be safe for human consumption, you need to cook it at a core temperature of 70°C for 2 minutes. Another name for this process is: ‘kill step’ or ‘full cook’ — cooking food for long enough to kill microorganisms by a magnitude of 6. So, if you want to ensure food is safe, a 6-log reduction, kill step or full cook is what you need.

Log reduction is important in the BRCGS standard which requies product entering a high risk area to have a 6 log reduction and a 2 log reduction when product enters a high care area. Additional guidance is given on risk zone and required log reduction in BRCGS Global Standard Food Safety Appendix 2.

Want to learn more about food safety?

Check out our range of BRCGS, Food Safety and HACCP courses by clicking the button below..

tolearn innovative Food Safety Management Platform

Book a tolearn Food Safety Management Management Platform live demo at a date and time which is best for you to see how tolearn can assist your company with onboarding of staff, employee competency and improve food safety culture.